Stirling Engines Could Save a Lot of Natural Resources

The

internal combustion engine has been accused of being an environmental

nightmare and the cause of much pollution and fueling it the cause of

much pollution and even wars. Many have advocated getting rid of it, but it does something valuable to our society that we can't afford to get rid of.

Electric

engines have always had a battery problem. And the batteries have to be

charged by something. But what if we could start on a path to

something better? Not a miracle cure for the world's ills but a

small step in the direction of less pollution, noise and waste.without

upsetting the status quo.

Progress

is an evolutionary process.Something is invented and then people start

using it and in the using and building of the item we find ways to

improve it. The longer something is used, the cheaper it becomes to make and the better it performs.

The

Stirling engine has languished in obscurity because when it was

invented it was impractical for most applications based upon power

output compared to its weight and size. It was improved upon until the

Internal Combustion Engine was invented with its much more powerful

cycle. At which point industry abandoned the Stirling engine and it

stopped evolving.

Before

people knew about pollution, natural resources depletion, global

warming and imported oil, the only performance measure that mattered

was power to weight ratio. The internal combustion engine, diesel or gas powered, got so far ahead in that race early on that it was the obvious choice to run our economy.

Today,

in 2015, the internal combustion engine has been improving for over 100

years and is a wonder of technical evolution because it originally had

better power to weight ratio or power density. And the Stirling is still a curiosity.

THE PROBLEM

Pollution

is waste and it doesn't pay. It costs money to make a mess and

then costs more to clean up. So avoiding the mess is worth the cost of

the wasted materials plus the cost of materials and labor to clean it up, assuming that you can clean up back to pristine condition.

The

amount of design and parts used to remove the pollution and noise from

the internal combustion engine is a significant portion of its costs,

the fuel that is wasted exceeds the fuel that is used.

THE CONCEPT OF TIDINESS

If

you make noise, you need to muffle it. So if you make a noisy engine,

you need a muffler and exhaust system. Stirlings don't make noise and

so don't need mufflers.

If

you burn fuel incompletely under varying pressure you need to treat the

exhaust to remove the unburned fuel and undesirable pollutants that are

produced. Stirlings burn fuel at low pressure under consistent

controllable conditions that allow for prevention of the formation of

undesirable pollutant exhaust gasses. The Catalytic converter is

built into the combustion area so very little fuel is wasted.

Stirlings

use the heat produced from the fuel, so it is possible to run them on

any heat source including Solar, Geothermal, gasoline, diesel, natural

gas, propane, wood pellets, corn or anything that produces heat.

If

you start and stop the combustion 2,000 times a minute, you need to use

energy to run a complicated ignition, timing system, that will inject

fuel, compress air and then light it at the right time. Stirlings

use a constant heat source that does not need constant attention and

control. You just start the burner and let it burn until it is time to

turn it off. Stilings don't need carburetors, fuel injection, intake

manifolds camshafts, EGR valves, PCV valves, Timing circuits,

distributors or sensors on the exhaust to name a few things that waste

money to buy and fuel to run.

Internal

Combustions Engines (ICEs) take in air, compress it, heat it until it

expands, use some of the force of the expansion to produce horsepower,

then dump most of the heat and pressure out of the exhaust manifold

while the rest wanders around and gets into the bearings and other

working parts of the engine. Stirlings have the heat sensitive

parts separated and protected from where the heat is used and the fuel

is burned so they don't need the mechanical parts cooled and the

compression is never released.

If

exhaust gasses are exposed to lubricants then the lubricants become

polluted and need to be changed. Stirlings have hermetically

sealed bearings that are never exposed to outside air or exhaust so they don't need oil changes and the bearings operate at ambient temperatures so they last a long time.

Internal

combustion engines have pistons that go up, down, up down (four

strokes) but which only produce power on the least efficient part of

one of the down strokes. The Stirling produces power at the most

efficient part of each and every up or downward motion of the piston.

So one Stirling piston does the work of 8 Internal Combustion

Engine pistons. Fewer parts doing more work.

Solutions

So

how much cheaper would an engine be if it didn't need all the things we

pointed out, like catalytic converter, ignition system, fuel injection

system, camshafts, valves, water pump or oil pump? How many natural

resources are used to build all those parts? It is time to find

out. Because, if you search Stirling Engines on the web, the one thing

you will notice, is that THEY WORK, but the design invented in

1816 just isn’t very powerful.

Engines

have one basic function, they convert one type of energy into another.

That is it. The internal combustion engine takes gasoline or

diesel and turns it into mechanical motion. The Stirling engine does the same thing more simply.

The

Stirling engine got stuck in an evolutionary backwater bereft of

attention after the internal combustion engine was invented. The

higher power density of the internal combustion engine made it seem the better choice.

Nobody

was concerned about the complexity of the design or the inefficiency

and pollution of the product because it performed a needed function as

an engine. Bandaid solutions were hurriedly invented and applied to the

Internal Combustion Engine to overcome its inherently unreliable, noisy

and dirty nature.

It

is as if someone invented Windows 1 and got to version 5 before people

realized that GNU/Linux could be used and they were too invested to

switch.

The

Stirling engine doesn't have the problems that the internal combustion

engines do but nobody could figure out how to make them as powerful.

The Stirling seemed hopelessly under powered but otherwise very

promising. Engines large enough to power ships were made. But the lower

power density made them uncompetitive with the noisier smoke belching

steam and then gas and diesel engines. Because time is money and fast

is better than slow.

Stirlings

have been made and operated in niche markets since their invention

while the internal combustion engine has been the engine of choice,

polluting the planet and consuming vast resources as it has

driven our economy.

Industrial

evolution has addressed the major flaws of the Internal Combustion

Engine. Engineers design and build models that last longer,

invented components that fix its drawbacks and allow it to produce

more power and work more reliably. The engine still has the problems,

we just don't notice them anymore. It would be much better for the

planet if we didn't spend all the resources necessary to cover up

the problems of the Internal Combustion Engine. It will never be

more efficient to use four strokes to do the work of one proper stroke.

One

curious property of the Stirling is that when you run it like a pump,

it pumps heat from one side to the other. Stirlings are efficient

at liquefying air when used in this matter. But with low power

density they haven't been used for things like your refrigerator or

your air-conditioner, where they would not use Ozone depleting gasses.

The

Stirling is reliable; with only about 4 moving parts there is very

little to break or go wrong. If only it had power density

comparable to the internal combustion engine it would save a massive

amount of resources and fuel.

At Last

Somebody

finally did something with the Stirling design. Unfortunately it was

the U.S. government. They made it more powerful and so expensive

that it can't compete with the lower costs modern internal combustion engine. So Stirlings are the engine of choice in spacecraft and submarines. I haven't been on either.

But,

now there is a new design, that in addition to being powerful is also

cheap and uses existing manufacturing infrastructure to make its parts.

But to build and promote it so that business will consider it when they could just use the internal combustion designs that everyone has been using forever will cost some money.

I

propose that this Stirling design needs to be built and used so that

businesses will look at how much they can save by using it and the

natural forces of the market can begin to cause its evolution into the power source of choice and perhaps make a small dent in the dominance of the internal combustion engine.

You

can research Stirlings and see that many different types have been

tried and they do actually work. But every one of them suffers from a

limitation in the working pressure and heat transfer area which is what governs the power output. This design fixes those issues.

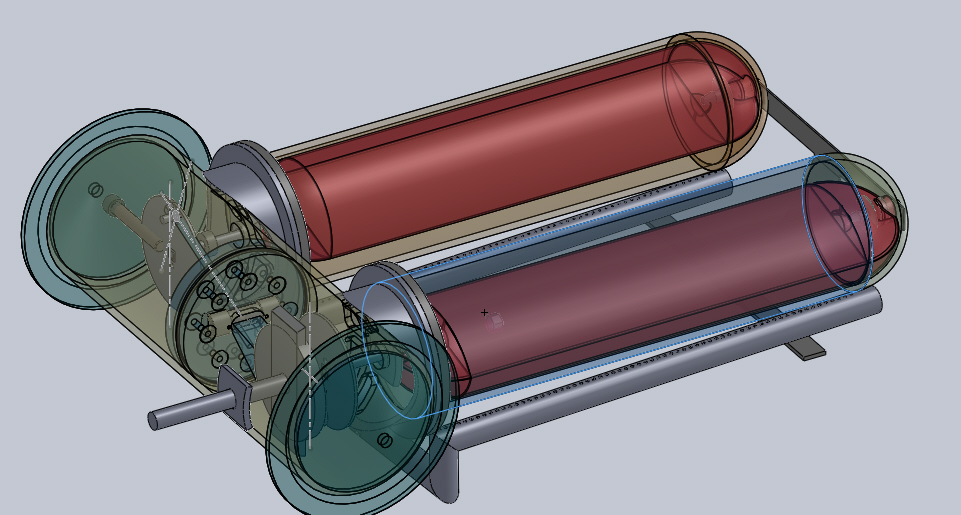

This

design is just a modification in the layout that puts two Stirling

engines back to back incorporating the Miller cycle so that the working

fluid can be used at high pressure. Just as the internal

combustion engine obtains its power density from operating with

high pressure so can this Stirling. The power density can be

adjusted with the operating pressure. Theoretically making this

Stirling engine more powerful than the Internal Combustion Engine.

|