Background

If you are unfamiliar with

the Stirling engine, use

your

search engine and you will discover that the Stirling engine is a very

promising technology that has never lived up to its potential because

of the high costs to manufacture, the low power output, and the

unresponsiveness of the engines. This design solves the power

density and costs issues.

These engines prefer to

run at one continuous speed which is

only moderately influenced by fuel input. Do not expect to

"rev"

your Stirling engine. Consequently, do not attempt to utilize

a

Stirling engine where there is the need for sudden acceleration, such

as in non hybrid cars or aircraft. You don't want to be

flying

your homebuilt airplane, stall, and then expect the Stirling engine to

save you. The response is simply too slow. Non

hybrid

aircraft propulsion is the best example of the wrong application for

this engine. Instead, choose the right application and you

will

love the economy and quiet operation that are the hallmark of the

Stirling.

Imagine an engine that

runs without the noise

of

fuel exploding out of the exhaust valves, instead, the fuel is burned

quietly similar to a gas log fireplace or your water heater.

No

complex plumbing of either fuel or air supply is needed. The

air

and fuel follow simple plumbing to the area where the heat is needed,

they combine continuously, efficiently, completely, cleanly and the

exhaust

gases are then plumbed away. No complex ignition system or

timing

circuits are required. With the Stirling's

continuous

flow, air and fuel valves don't open and close every time the

piston completes a stroke. Instead of controlling air, fuel,

and pressurization

each stroke of the piston, the Stirling controls the heat energy of the

fuel after the fuel and air are combined. Moving the working

gas

inside from the heating area to the cooling area is much simpler and

more efficient than creating heat exactly where and when it is needed

for each stroke of the piston and then wasting most of it out the

exhaust ports. This is the most difficult part of

Stirling operation to grasp; Air can be heated and cooled

(causing expansion and contraction) over 1500 times a minute.

Search u tube.com for videos that prove that this is true and that

these

engines actually work. Once you grasp this concept, the

Stirling's simplicity will enchant the engineer in you.

The

internal combustion engine has, until now, overshadowed the Stirling

engine

in performance with the ability to process chemical energy into motion

at a much higher rate and in a more compact form. A four

cylinder

gasoline powered internal combustion engine can convert a gallon of gas

into work in under 15 minutes. The Stirling engine has always

had

a bottleneck in the energy input that prevented compact high volume

throughput of energy. This design directly addresses that

bottleneck as well as some of the complexities that made the Stirling

engine expensive to produce.

|

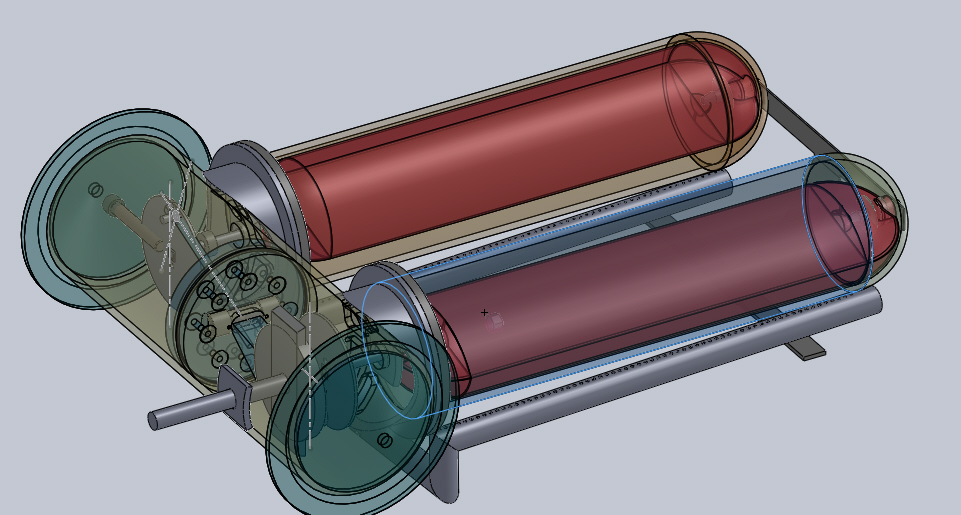

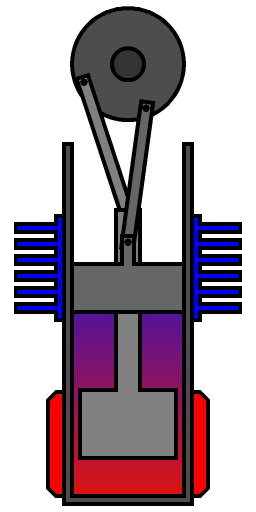

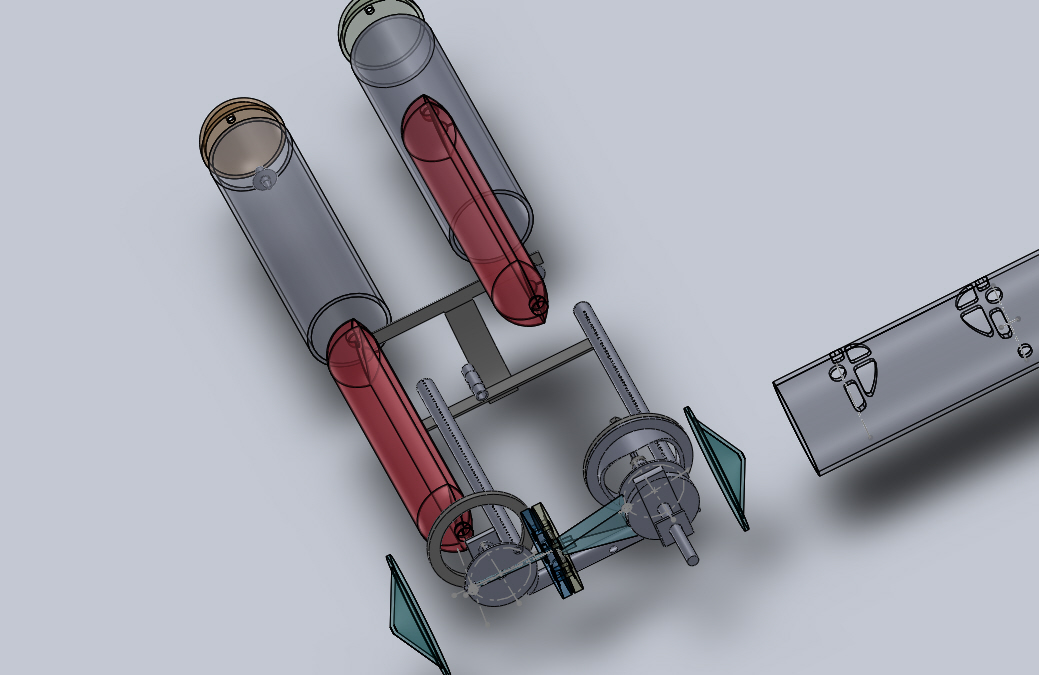

A

traditional design for reference.

compare to the internal combustion engine.

Fewer parts finaly means lower costs, (just as soon as we get the

volume )

Parts that the Stirling engine doesn't need:

seperate starter, (utilizes the alternator),

fuel injection system (burns like a Coleman (R) stove),

complex ignition system (just one

piezo electric spark to start the heat source),

high pressure fuel pump,

turbo charger,

valves,

timing belt,

camshaft,

rocker arms,

oil pump,

oil filter,

oil pressure monitor,

check engine light,

intake manifold,

exhaust manifold,

catalytic converter ( catalyst used in combustion area),

EGR valve,

oxygen sensor,

muffler

Maintenance that the Stirling doesn't need:

Oil changes,

spark plug changes,

timing belts, valve adjustments,

ignition wires,

oxygen sensor,

check engine light

|

|

Applications

Stirling engines run on any heat

source, from geothermal

to solar to propane to wood. Anything that produces heat can

potentially power this engine. Consequently, if you have

waste

heat, why not use it to power your lights and heat your water?

Stirling engines are quiet and

reliable. If you

need a portable generator for a mobile home, off the grid homes and

offices or trade shows, consider the Stirling. The cooling

cycle

of the engine can be plumbed to provide you with hot water.

Running

a Stirling engine in reverse, causes it to pump

heat from the hot side to the cold side. This is how

commercial

cryocoolers work to convert air into a liquid. This design

can be

used as a heat pump, either cooling or heating fluids as

desired.

If you have need of refrigeration and don't have electricity, this

design can be adapted to produce power from fuel on one side and heat

pumping on the other. If you have a noise issue with

conventional

refrigeration, or want to use non polluting refrigerant gases , this

might be the ticket.

Just as important as when Stirling engines make sense is

recognizing when they don't. Stirlings are only moderately

responsive to fuel input. Do not use this engine where

responsiveness is an issue. |

Possible engine

fuel source

"...it was a pit

fire with poop. The pot doesn't smell like poop, it smells like a

mesquite fire because the cows like to eat the mesquite beans from the

trees."

(http://www.craftster.org/forum

/index.php?topic=318202.0)

|

History

The Stirling

engine has been around in

various forms since

1817 when Robert Stirling patented his first design. Even

earlier

variations of this device are speculated to have been employed to

move massive

doors in Roman temples over

2000 years ago.

Current designs are found in cryocooling,

home

energy generation, solar

power generation, submarine

propulsion, and space

craft power generation. Attempts to utilize the Stirling

engine

in automobiles were unsuccessful. This may have been due to a

tendency to treat the Stirling engine as a poor substitute for the

internal combustion engine. A more appropriate alternative is

to

treat the Stirling engine as a unique power source;

certainly,

its distinctive characteristics recommend it to a variety of

applications entirely outside the realm of the internal combustion

engine. Just as the electric motor and the turbine are each

uniquely suited for certain tasks, so too is the sterling engine.

Two variables have heretofore inhibited the widespread

adoption

of the Stirling engine - cost and power density. Lower

manufacturing costs and increased power output, give the

Solar-Miller (tm)

Stirling engine a competitive edge over all previous

applications.. |

Robert

Stirling

A quick word on

maintenance and

repair. little. That is right, these engines are

sealed

at the factory, you can't open them beyond re-pressurizing the working

gas. The bearings are located away from the heat source and

have

very little stress on them. The output shaft seal, if you are

using a sealed one can be changed without accessing the inside of the

engine. If you manage to break the output shaft, or drop

something on the case that bends it, or drill a hole into it, well,

they don't cost that much. On the other hand, if you

recover the engine after it has been submerged in water, simply hose it

off and you are good to go.

And they are designed to be recycled.

|